|

Diamond

What

is diamond?

What is synthetic diamond?

What is the ways to synthesize diamond?

What is the characteristic of different synthetic

ways?

What ways does SUKAN adopt to synthesize diamond?

What is synthetic single crystal diamond?

What is the atomic structure of Synthetic Single

Crystal Diamond?

How is diamond size measured?

What is the standard to classify the quality of diamond?

What is the application of different standard diamond?

What is coated diamond?

Why are some ultra-hard grits metal coated?

What is PCD ( Polycrystalline Diamond)

What are the main applications for PCD?

What is diamond Micron powder?

What is the application for diamond Micron powder?

What is diamond?

What is diamond?

A natural and synthetic

mineral composed of carbon atoms in a specific crystalline structure.

it is the physically hardest substance known and is now widely

used as an abrasive in high productivity tools in industry.

Diamond also has remarkable physical

properties such as:

Density (g/cm3) 3.52

Compressive strength (GPa) 8.68

Fracture toughness (MPam1/2) 3.40

Knoop hardness (GPa) 57 - 104

Young's modulus [GPa] 1141

Thermal expansion [10-6K-1] 1.5 - 4.8

Thermal conductivity [Wm-1K-1] 500 ¨C 2000

Wear coefficient 2.14 - 5.49

What is synthetic diamond?

What is synthetic diamond?

Synthetic diamond can be synthesized using techniques, which emulate

the natural geological growth of diamond. This involves using

high pressure/high temperature (HPHT) synthesis process, which

converts the soft graphite carbon into the very hard crystalline

form of carbon - diamond (crystallization) or direct conversion

using explosives to generate short duration pressure and temperature

shock waves. Various industries take advantage of diamonds remarkable

physical properties. Principal mechanical applications are sawing,

drilling, grinding, cutting, lapping and polishing, truing.

What is the ways to synthesize diamond?

What is the ways to synthesize diamond?

There are many ways to synthesize diamond, but only a few technologies

are adopted in Ultra-hard Materials industry. Synthetic diamond

can be produced through high temperature and high pressure or

made through its growth on inferior stable condition. The technology

by high temperature and high pressure can be divided into two

kinds: one is to synthesize diamond through stable pressure with

catalyst and the other is to produce diamond directly. The technology

to make diamond on inferior stable condition of diamond can be

classified to two kinds: one is that diamond is produced by its

growth in thin film shape on low pressure, and the other is that

diamond is synthesized on ordinary pressure and high temperature.

What is the characteristic of different

synthetic ways?

What is the characteristic of different

synthetic ways?

The technology of producing diamond on stable pressure with catalyst

is that: on condition of thermodynamic stability of diamond, synthetic

diamond is produced through high temperature and high pressure

(by belt-type press or cubic press) with graphite as raw materials

and metal/alloy as catalyst. Most of ultra-hard material companies

(about 90%) adopt this way to produce synthetic diamond.

The technology of producing diamond directly through stable pressure

does not use catalyst, but it needs higher pressure and temperature

and thus needs better press, so it is not widely adopted in trade.

The technology of producing synthetic diamond on high pressure

and temperature realized by detonator explosion can produce micron

diamond crystal which is often imperfect and brittle. This technology

does not need expensive equipment and can realize high productivity,

but it is difficult to control temperature.

What way does SUKAN adopt to synthesize

diamond?

What way does SUKAN adopt to synthesize

diamond?

SUKAN synthetic diamond is produced through stable

pressure with catalyst by belt type press and cubic press with

sheet graphite or powder graphite as material.

SUKAN RSD diamonds, produced with best raw materials

by belt type press, reach the highest level of quality standard.

Their best characteristics, including low impurities, improved

shape and color, excellent toughness index and thermal toughness

index, make them especially suitable for High Temperature Sintering.

SUKAN RBD diamonds are produced by cubic press.

They have similar properties with RSD series, thus provide an

economical choose of high grade diamond grit, and it is ideal

for low temperature sintering.

SUKAN RMD diamonds are medium quality diamond grits with

a wide range of usage and good performance in each particular

application, including drilling, sawing and grinding.

SUKAN RRB diamonds have superior bond retention

for their sharp shape, and are self-sharpening for their friability.

They are suitable for grinding and polishing non-ferrous materials.

What is synthetic single crystal

diamond?

What is synthetic single crystal

diamond?

Synthetic single crystal diamond

is manufactured for industrial applications. It¡¯s produced by

high pressure / high temperature (HPHT) synthesis process and

strictly controlled crystal growth conditions. Repeatable physical

characteristics and dimensional consistency are the notable features

of synthetic single crystal diamond. For example, SUKAN offers

various series of synthetic single crystal diamond such as RSD/RBD/RMD/RRB

series. To know the detail the products, please feel free to view

the products column in our website.

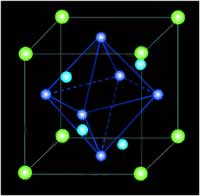

What

is the atomic structure of Synthetic Single Crystal Diamond?

What

is the atomic structure of Synthetic Single Crystal Diamond?

Synthetic

single crystal diamond has an identical physical structure to

that of natural single crystal diamond. The basic diamond atomic

structure, described by its unit cell, can be pictured as a face-centered

cube (as shown above) with a carbon atom in the middle of each

face and four more atoms arranged diagonally opposite each other

in pairs, with the upper plane offset at a right angle to the

lower plane. Unlike graphite, the individual planes are not flat

but corrugated. In diamond, each carbon atom is connected to four

other carbon atoms by covalent bonds. In the simplest case, these

four atoms form a perfect tetrahedron. Due to covalent bonding

between the atoms there are no free electrons and synthetic diamond

is normally not electrically conducting. In the case for synthetic

diamond, one or more of the carbon atoms might be replaced (or

substituted) with nitrogen atoms, giving the diamond a yellow

color.

How is diamond grit measured?

How is diamond grit measured?

Diamond abrasives are traditionally sold in US mesh size ranges,

these mesh sizes are defined by the mesh size of sieves used to

separate the diamond particles. The sieve sizes are graduated

and defined by the number of lines per inch of each sieve e.g.

50 lines per inch or 20 lines per inch. The diamond is then sold

in overlapping mesh size ranges. This means for example in a sample

of 40/50 US mesh diamond most of the material would fall between

the 40 mesh and the 50 mesh sieve. International standards permit

that a small amount of oversize and undersize material is permitted,

but this is usually no more than 2-4%.

What is the standard to classify the quality

of diamond?

What is the standard to classify the quality

of diamond?

There are a few kinds of criterions to classify the quality of

diamond, including crystal shape, strength, impact toughness,

thermal stability, etc. So diamond always is classified into a

few series according to their characteristics, for example, SUKAN

diamond can be classified into RSD, RBD, RMD and RRB series.

What is the application of different standard

diamond?

What is the application of different standard

diamond?

Diamond grit always is applied in different use area according

to its quality characteristic. The diamond series from SUKAN can

make good example to explain it. SUKAN RSD series, because of

their low impurities, improved shape and color, excellent toughness

index and thermal toughness index, are especially suitable for

high temperature sintering and made of geological drilling or

various saws. SUKAN RBD series are good for sawing and drilling

application and they are ideal for low temperature sintering to

be made of tools to machining granite, concrete, tough marble.

SUKAN RMD series are medium quality diamond grits and are suitable

for wide range of application such as grinding and sawing of glass,

marble, rock. SUKAN RRB diamonds have superior bond retention

for their sharp shape, and are self-sharpening for their friability.

They are suitable for grinding and polishing non-ferrous materials.

What is coated diamond?

What is coated diamond?

Coated diamond refers to the diamond with metal coverage on the

crystals, and coated diamond is highly adhesive in bond system

and better thermal stable. Thus the tools life and processing

cost are remarkably improved. SUKAN can offer various coated diamond

with upon request.

Why are some ultra-hard grits metal

coated?

Why are some ultra-hard grits metal

coated?

Metal coating can be classified two kinds. One is Metal cladding

comprising a thick layer of typically nickel or copper which can

be up to 60% of the total particle weight. These clad particles

are generally used in resin bonded tools such as grinding wheels.

The effect of the cladding is to improve the retention of the

abrasive in the bond and help dissipate the heat generated during

grinding and hence improve performance of the tool. Another is

Metal coating comprises a thin layer of metal, such as titanium.

When used in bonds which use high temperatures during their manufacture

such as some metal and vitrified bond systems these coatings can

improve particle retention and protects the diamond during manufacturing

of the tool/segment.

What is PCD ( Polycrystalline Diamond)

What is PCD ( Polycrystalline Diamond)

PCD

refers specifically to diamond particles which have been sintered

together into a coherent structure using a chemo-mechanical binder

and high-pressure, high-temperature conditions similar to those

used in single crystal diamond synthesis. These sintered PCD materials

have extensive range of uses, most notably for cutting tools machining

non-ferrous metals and non-metallic materials and for wear parts.

An advantage of these materials is that their structure and composition

can be engineered to have properties tailored to specific applications

and operations. SUKAN can offer PCD specified by customers, and

PCD with metal layer formed on the surface available upon requests.

What are the main applications of PCD?

What are the main applications of PCD?

The best application of PCD can be classified three kinds of area

as below:

(1) Cutting non-ferrous metals and alloys.

(2) Cutting wood particle board (particularly medium density fibreboard

- MDF, and chipboard in the furniture industry).

(3) Non-cutting applications such as wear-parts.

What is diamond Micron powder?

What is diamond Micron powder?

Diamond micron powder refers to very fine abrasives made of diamond

crystal. They are used, for instance, in precision machining and

polishing applications. Applications include the use of micron

diamond as loose powder, in for instance polishing, or in bonded

tools, such as grinding wheels. Sukan can supply a variety of

diamond Micro powder product.

What

is the application for diamond Micron powder?

What

is the application for diamond Micron powder?

Diamond Micron powder is used extensively in electronics, aviation

and space flight, optical instrument, glass, ceramics, petroleum,

geology and other fields. Diamond Micron powder is the best material

for grinding and polishing hard alloy, ceramics, gem stones and

optical glass.

|